Commerce Partners with Industry to Advance Smart Manufacturing

Montana businesses are successfully leveraging advanced smart manufacturing to make their businesses more agile, thanks to a 2024 federal grant award which creates opportunities for Montana manufacturers, schools and colleges to see, learn about and interact with innovative tools.

“Smart manufacturing moves businesses into the future, lowering manufacturing costs, increasing precision and production capacity and enabling manufacturers to compete in an ever-more advanced global market,” said Montana Department of Commerce Deputy Director Mandy Rambo. “Montana is poised to take its place on the front line of smart manufacturing technologies, and Commerce’s support and expertise will be an essential part of that.”

Smart manufacturing refers to automation and technologies that facilitate and expedite manufacturing processes and related operations. These advancements often replace hard-wired equipment with wireless systems. They enhance integration so interconnected systems can generate, analyze and share key data site-wide for further refinement. Smart manufacturing is an important component of Industry 4.0, a broader term for the transformation of all aspects of modern industry through ultra high-tech equipment and systems, innovation and big data.

Common examples of smart manufacturing include 3-D printing, automated robots, robots to work alongside humans, maintenance systems that use sensors to predict potential failures in advance and machine learning systems that identify defects. For manufacturers, these updates can save time and money, raising their bottom line and boosting their competitive position in national and international markets.

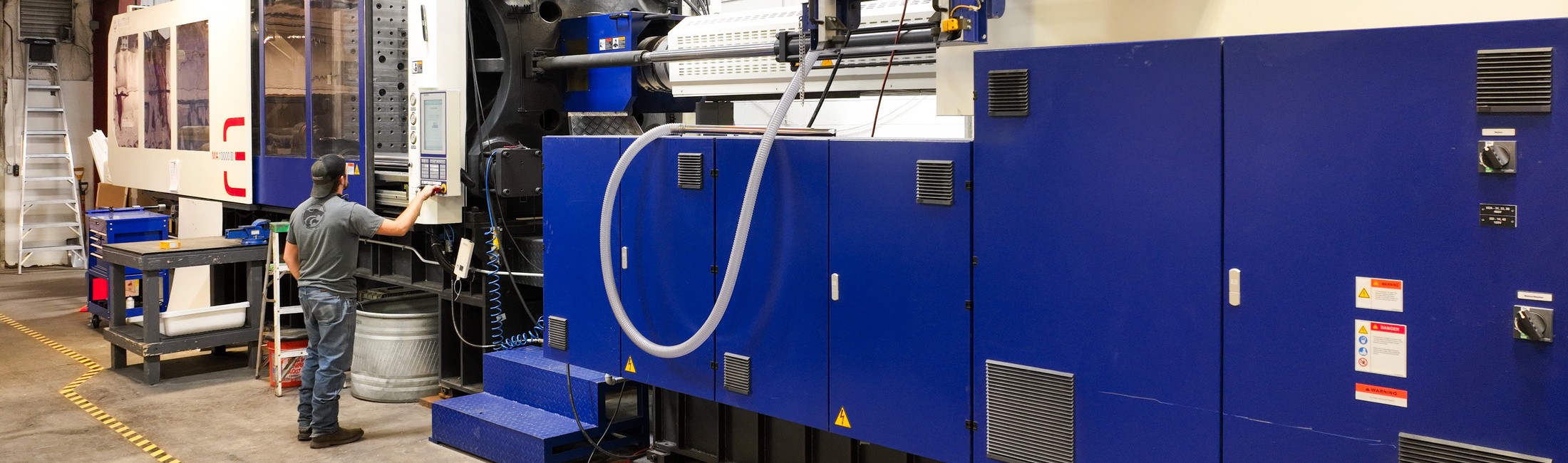

To promote the growth of the manufacturing sector in Montana, state agencies offer financial and technical support to manufacturers to facilitate the adoption of these advanced business solutions. Commerce leads the Montana Automation Loan Program, a low-interest loan program to help upgrade, replace or expand equipment that would modernize their operations and promote company growth. Diversified Plastics, a manufacturer of custom plastic products in Missoula, used this program to purchase an additional plastic injection molding machine, which resulted in the increased capacity and shorter lead times needed to meet demand in new markets. Red Oxx in Billings, which specializes in hand-crafted, durable bags and gear for travel, work and recreation, used the loan program to buy a CNC material laser cutter. The cutter automates many of the material cutting and pattern making steps previously done by hand. The significant time savings allows Red Oxx to reduce backorders, as well as design and prototype new products much more quickly.

Commerce also gives $750,000 annually in support of the Montana Manufacturing Extension Center, which assists manufacturers with trainings and technical assistance, including guidance on smart manufacturing. For example, MMEC has conducted 3-D Matterport scans at 10 manufacturing companies and partner organizations over the past year to show them potential applications related to enhanced facility layout, inventory management, materials movement and other process improvements.

A new program supporting smart manufacturing is underway. The U.S. Department of Energy awarded the Montana Department of Environmental Quality a Smart Manufacturing Technologies Outreach Initiative grant to expand Industry 4.0 capabilities statewide. DEQ, MMEC and Highlands College in Butte are partnering to help Montana manufacturers learn about and adopt a variety of cutting-edge solutions.

The goal of this initiative is to offer information and assistance to small and medium-sized manufacturing firms who may not be aware of the state-of-the-art tools available to them or who need technical guidance to select, design or implement an advanced project.

In the first phase, MMEC created a mobile technology van, which its business advisors have begun driving around the state to demonstrate the potential applications of 3-D printers, scanners, advanced sensors and other innovations. MMEC will follow up with guidance to manufacturers to help them plan, select and use smart manufacturing tools.

The outreach and education efforts of this grant will include a statewide workshop, a new internship program, a smart manufacturing apprenticeship and a forthcoming one-year certificate program at Highlands College.

For more information about Commerce programs that support manufacturing and business success, visit commerce.mt.gov.

Tags: Article